Fumigation Monitoring Equipment

Fumigants by their very nature are toxic substances, as they are used to control pests in silos, containers, and other bulk storages of agricultural and horticultural crops. Most fumigants are colorless and odorless gases which makes it impossible for the human senses to detect.

Uniphos fumigation equipment is available for a wide range of applications in the fumigation industry, whether it is for checking leaks during the fumigation process, for personal protection, or for continuous monitoring.

Apart from the need to monitor fumigant concentrations for health and safety reasons at the time of applying the fumigant and outside the fumigated structure, the need to monitor concentrations inside the fumigated structure to ensure successful fumigation is equally important.

These gases if not monitored will have serious consequences. Hence, the dangers of fumigants are very real for human beings. It can lead to a fatal accident if someone enters a building being fumigated or that has not been properly vented afterward.

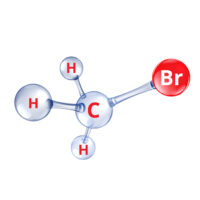

Few of the gases that are used as fumigants are:

- Phosphine and Sulfuryl Fluoride, which are both extremely toxic

- Methyl bromide, which apart from being toxic also depletes the ozone layer.

The main reasons that we need to detect and/or monitor fumigants are

For personal safety and protection

Poor warehouse design, uneven stack, or defective fumigation covers can cause leakage of the fumigants from the fumigated space and thus causing fumigation failure. Even minimal inhalation of these fumigants by working personnel can cause a feeling of sickness, nausea, and tightness in the chest, and extended exposure can have long term negative effects on their health. Hence checking for leaks during the entire fumigation period is of utmost importance for personal safety and protection. Here one needs to monitor fumigant levels in the TLV levels, which are in the sub-ppm or low-ppm levels.

For process control measurement

The fumigant is supposed to be confined for the intended duration of exposure at a pre-defined concentration to achieve the lethal dose needed to control the target pests in Containers, Bulk storages, Silos, etc. To ensure successful fumigation, the need to continuously monitor the gas concentration of Fumigants in the fumigated area is of utmost importance. Here one needs to monitor fumigant levels in lethal concentration levels, which are in hundreds and thousands of ppm.

FAQ's

What are fumigation monitoring instruments?

Fumigation monitoring instruments are specialized devices designed to ensure the safety and effectiveness of fumigation processes. These instruments are designed to measure and track the concentration levels of fumigants in and around the fumigation area during fumigation procedures. By providing real-time data, they help fumigators maintain precise control over the fumigation process, ensuring that the right amount of fumigant is used and that it remains within the required limits.

These fumigation instruments come in various types, viz. gas detectors for personal safety, tabletop monitors for fumigation process monitoring.

What are the basic fumigation procedures?

The basic fumigation process involves several key steps. First, the area to be fumigated must be sealed securely to prevent the escape of fumigants. Next, the appropriate fumigant, such as phosphine or sulfuryl fluoride, is introduced into the enclosed space.

Monitoring the fumigant concentration is crucial to ensure it reaches the required levels for effective pest elimination. This is typically done using fumigation monitoring equipments. The fumigation process is closely monitored to ensure safety and compliance with regulations.

After the exposure period, the space is ventilated to remove any remaining fumigants, making it safe for humans and animals to re-enter. Thorough aeration is necessary before unloading the treated goods. For successful fumigation, it is vital to follow these procedures meticulously and use reliable monitoring equipment to achieve optimal results and maintain a safe working environment.

Why is monitoring important during fumigation?

Fumigation involves the use of toxic gases or chemicals to eliminate pests, insects, or pathogens in enclosed spaces. Without proper monitoring, there could be potential risks to human health and the environment.

By closely monitoring the fumigation process with the help of fumigation instruments, we can verify that the concentration of fumigants remains within safe limits and doesn’t pose any harm to occupants or nearby surroundings. This helps prevent accidents, exposure to harmful substances, and potential damage to property.

Apart from the safety reasons, monitoring during fumigation is essential for effectiveness, compliance, and environmental protection. It provides real-time data and insights that allow fumigators to make necessary adjustments, ensuring that the fumigation process is both successful and conducted with the highest regard for safety and environmental responsibility.

What are the safety considerations when using fumigation equipment?

When operating fumigation instruments, it is crucial to prioritize safety measures to ensure the well-being of the individuals involved. Firstly, it is Important to have at least two people present during the fumigation process. This ensures that one person can always be outside the fumigated area to provide assistance or seek help if needed. Secondly, the use of personal protective equipment (PPE) is highly recommended, including respiratory masks, gloves, and goggles to prevent exposure to fumigants.

Proper ventilation is vital to minimize the concentration of fumigants in enclosed spaces. Adequate ventilation helps disperse harmful gases and maintains a safer environment. Moreover, having emergency procedures and communication systems in place is critical. Everyone involved should be familiar with the protocols to follow in case of accidents or unforeseen circumstances.

How can I ensure the accuracy and reliability of fumigation monitoring equipment?

Invest in high-quality equipment from reputable manufacturers; one of them is Uniphos Envirotronic, whose products are known for their precision and performance. Regular calibration of the monitoring devices is paramount, as this guarantees accurate readings over time.

Keep the fumigation equipment in a controlled environment when not in use, protecting it from extreme temperatures or moisture. Follow the manufacturer’s guidelines for storage and handling. Training your staff on proper usage and maintenance is equally important. Educate them on handling procedures and potential errors that could impact results.